Several firms tested Elcora’s graphite for electrical car battery applications. The results are fantastic! It was concluded that Elcora’s graphite suits the quality requirements to be used for car batteries.

Graphite

- Traditionally, China has been the biggest graphite producing and processing country. However, the current processes used in China are no longer meeting the exceedingly difficult requirements on quality and environmental impacts from the electrical car and battery manufacturers like Tesla and others. See Products

- No Chemical Processing.

- High purity with essentially no silica contamination.

- Excellent graphite source for battery and high-end applications.

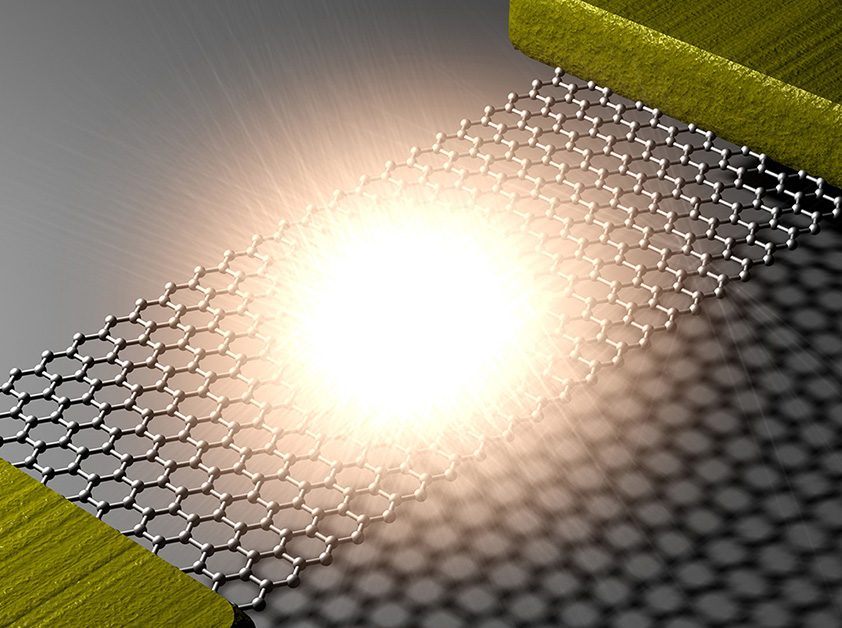

Graphene

The Centre for Advanced 2D Materials (CA2DM) at the National University of Singapore (NUS) tested Elcora’s graphene. CA2DM has been dedicated to graphene R&D since 2010 and has received over 200 million dollars in funding. It is reported that the director of CA2DM, Dr. Antonio Castro Neto played an important role in informing the Nobel committee regarding whether the Nobel Physics Prize should be awarded to Russians Andre Geim and Konstantin Novoselov of Manchester University in 2010. In recognition of Dr. Castro Neto’s contribution to the graphene industry, Science For Brazil (scienceforbrazil.com) named him the “Graphene Godfather”.CA2DM tested a large number of graphene samples from suppliers worldwide including well-known commercial producers from North America and Europe.

Global Industry Leading Quality

55% graphene content, consistent sizes, averaging 3 layers

Made from natural graphite, much higher quality than Graphene Oxide

It was concluded that Elcora’s graphene is the best quality in all areas tested, including the percentage of graphene content, average number of layers, and consistency in size.